Roadshow 2023 schedule announced

We are excited to announce our revived Roadshow that will travel down the East Coast of Australia.

19th June 2023

We are excited to announce our revived Roadshow that will travel down the East Coast of Australia.

19th June 2023

There are many different techniques available for the detection, quantification and identification of microorganisms and the aim of this review is to discuss some examples which can be used within the oil and gas industry readily.

26th March 2023

We are pleased to announce that the Water and Waste Water Technical Group is being reactivated to address the Corrosion challenges faced by the industry. After a brief hiatus, the ACA...

16th March 2023

The Call for Awards is out and we’re looking for your nomination. With the Corrosion & Prevention 2023 Conference coming up quickly in November of this year, it’s time to...

14th March 2023

Corrosion is a natural process that can have significant consequences for the performance and lifespan of various materials.

1st March 2023

Over 100 registrants from 17 countries participated in our first Technical Group event of 2023, a webinar about “Latest Insights into Microbial Influenced Corrosion (MIC) Monitoring Techniques” held on the 14th February...

21st February 2023

The ACA is launching a course that introduces the theoretical and practical aspects of preventing, managing and inspecting corrosion under insulation (CUI).

17th January 2023

his webinar features two fantastic guest speakers, Dr Thunyaluk (Kod) Pojtanabuntoeng, discussing some of the Recent Developments in CUI Research from Curtin Corrosion Centre and joining us from the UK, Dr Prafull Sharma, Chief Technology Officer of CorrosionRADAR spoke about Corrosion Under Insulation Risk Analytics with Monitoring Systems using Electro-Magnetic Guided Radar (EMGR). Earlier this year (2021), CorrosionRADAR won the Materials Performance (MP) / Association for Materials Protection and Performance (formerly NACE) Corrosion Innovation of the Year Award for its ground-breaking Predictive Corrosion Under Insulation (CUI) Monitoring System – a next generation technology solution that is transforming the global response to the enormous industrial challenges created by CUI.

15th November 2021

Nicholas, being only a few months into has a unique perspective of a newcomer, but already has a great foundation of technical knowledge. Nicholas discusses a recent project undertaken about Nickel-Cadmium battery testing and refurbishment for pipeline protection. There will be a Q&A after his presentation too.

15th November 2021

The NSW Branch’s invited a panel of experts for an evening discussion of Concrete Corrosion and Durability. Each panellist has a career of experience in the protection of concrete structures...

28th September 2021

The ACA's Oil and Gas Technical Group was thrilled to Host Peter Bock for a presentation on Third Generation Polysiloxane Technology. Third Generation Polysiloxane (TGPS) ambient curing CUI mitigation coatings have been used in the petrochemical and processing industries for over five years since the “third generation” concept was introduced at NACE Corrosion 2017. These coating technologies have demonstrated positive results in both shop and field application for asset management in elevated temperature, cryogenic and cyclic applications across -196 to 650o C/ (-321 to 1200o F) operational temperatures. TGPS coatings have also demonstrated effective use of a two-step (primer-insulation) CUI mitigation coating approach operating up to 400o C/750o F, when compared to the traditional (CUI coating-fibrous insulation-cladding) systems.

5th September 2021

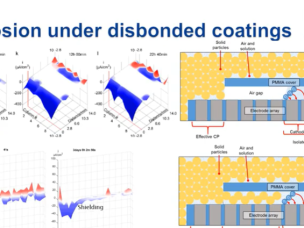

Presenter Facundo Varela, also known as Bob, is a research fellow at the Institute for Frontier Materials at Deakin University. His completed PhD project focused on new electrochemical methods for monitoring localised corrosion under cathodic protection. As a research fellow, he is working on an Energy Pipeline CRC sponsored project aiming to perform field trials of the sensors developed during his PhD.

9th August 2021

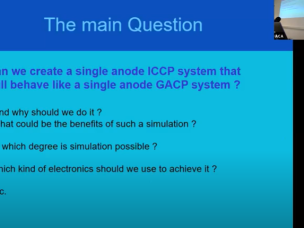

Presenter Rajko Vukcevic is an independent CP researcher and innovator. He was involved in design and development of electronics systems and equipment for ICCP used in marine, concrete and pipeline applications, for 15+ years in Australia. He has 35+ years of electronics design experience in switch-mode power solutions. He invented the Current Multiplier based Power Distribution System for marine ICCP applications. He holds an M.S.(Elec Eng) degree from Belgrade University, Serbia and is a long-time a member of ACA.

9th August 2021

Presenter Ramon Salazar is a Senior Materials Engineer at South Australian Water Corporation. He has more than 25 years’ experience in the corrosion control field, focusing on cathodic protection, concrete degradation and non-metallic materials. He is currently the chairman of the South Australian Electrolysis Committee. He has an Engineering degree from Simon Bolivar University, Venezuela and is a chartered professional member of Engineers Australia. He is also NACE CP4 Cathodic Protection Specialist.

8th August 2021

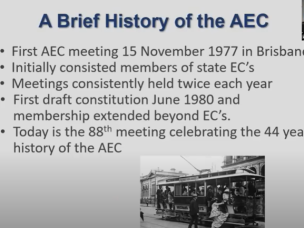

Presenter Dr Bruce Ackland is a Corrosion and Cathodic Protection Scientist, he obtained a Bachelor of Science with Honours in Physics at Monash University in 1979 and a Doctor of Philosophy in 1984, also at Monash University in the Department of Materials Engineering. Bruce has worked in the corrosion and cathodic protection industry since 1982, forming Bruce Ackland and Associates in 1985. Cathodic protection projects have involved work throughout Australia, New Zealand, Asia, the Middle East and North Africa. Bruce maintains an active role as a member and chairman in Australian Standards committees; is the current Chairman of the Australian Electrolysis Committee and is an accredited ACA lecturer and Corrosion Technologist.

8th August 2021